GREIGE FABRIC INSPECTION / CHECKING MACHINES

GAS SINGEING MACHINE

Singeing is a process applied to fabrics to produce an even surface by burning off projecting fibres, yarn ends and fuzz. Our machine is equipped with double jet ceramic imported burners which provide the best results for this process.

DESIZING MACHINE

CONTINUOUS BLEACHING RANGE - CBR

CONTINUOUS MERCERIZING MACHINE

SUEDING FINISH MACHINE

JIGGER DYEING MACHINES

ROTARY PRINTING MACHINE

CONTINUOUS AGER MACHINE

Polymerizing cum Ager Machine

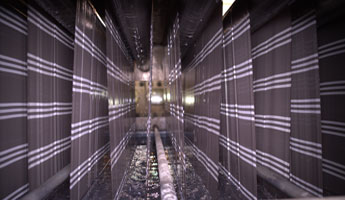

CONTINUOUS PRINT WASHING RANGE

HOT AIR STENTER

CALENDERING MACHINE

SANFRONAZING (PRE-SHRINKAGE) MACHINE

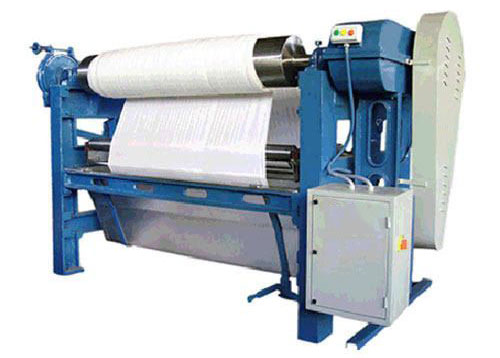

FABRIC INSPECTION AND ROLLING MACHINE

ROLL PACKING MACHINE

LABORATORY

Our company has an in-house fully equipped Laboratory for testing of greige fabric, dyes / chemicals, final products and environmental parameters of the treated wastewater, operated by qualified & experienced technicians.

We are testing each & every sample of greige fabric so far as its count / construction, width, weight (GSM or GLM) is concerned. Every supply of raw material including dyes / chemicals used for processing of the fabric are also tested with its standard / previous supply for consistency results. Finally, we have strict system to allow the packing of final finished fabric in our premises only after checking all the parameters tested in our in-house laboratory for its colour fastness (i.e. dry / wet rubbing) including washing fastness, tearing strength, tensile strength, residual shrinkage of finished width etc.

BOILERS – ESP (CARBON CREDIT)

PLC based with auto fuel injecting system Coal Fired Steam Boiler of required capacity. This is basic necessity to provide optimum steam heating (energy) for various processes on the majority machineries.

GSPL strongly believes to maintain the rules of environment friendly atmosphere as per direction prescribed by Government under Pollution Control Boards and accordingly, GSPL Boiler house is fully equipped with all the Air Pollution Control equipments (incl. ESP).

Effluent Treatment Plant

GSPL has own fully equipped effluent treatment plant (ETP) in the premises. The plant is installed since inception of the unit and working efficiently throughout 24/7 for treating the waste water generated out of various processes. GSPL is holding the lifetime membership of NTIEM to dispatch the treated waste water for further treatment to the Common Effluent Treatment Plant (CETP) facility provided by NTIEM.

NTIEM (Narol Textile Infrastructure & Environ Management) has setup of Asia largest Common Effluent Treatment Plant (CETP) and collect the effluent generated from approx 125 unit / members as well as continuously operating the CETP to achieve norms prescribed by the Govt. Prior to discharge the water in the river.